WB MONO MS Performance Plus vs Bona R851: Wood Flooring Glue Comparison for Edmonton Projects

Introduction:

Choosing the right adhesive is crucial for a successful glue-down hardwood floor installation – especially in Edmonton’s climate. Homeowners, contractors, and flooring suppliers in Edmonton, Alberta need a reliable wood flooring glue that can handle temperature swings and ensure a long-lasting bond. Two top contenders on the Canadian market are WB MONO MS Performance Plus and Bona R851. Both products are advanced wood floor adhesives available in Canada (through Edmonton-based suppliers and nationwide distributors) and offer high performance for hardwood flooring installations. In this article, we’ll compare WB MONO MS Performance Plus and Bona R851 side by side – covering their features, application methods, trowel requirements, coverage, ease of use, performance, environmental attributes, drying times, and suitability for different wood types and subfloors. We’ll also provide practical tips on how to apply these adhesives, so you can make an informed choice and achieve a professional result.

WB MONO MS Performance Plus Wood Floor Adhesive Overview

WB MONO MS Performance Plus is a one-component (monocomponent) silane-based adhesive manufactured in Italy by Adesiv. This 100% MS polymer adhesive is specifically designed for bonding all types of wooden flooring – from solid hardwood planks to engineered wood and parquet – to a variety of subfloors. It adheres well to concrete slabs, plywood or chipboard, and even to non-absorbent surfaces like existing marble, ceramic tiles, or terrazzo flooring. In fact, if applied evenly as a full layer, WB MONO MS Performance Plus creates a waterproof barrier that helps prevent moisture (rising damp) from concrete subfloors from affecting the wood. This dual functionality (adhesive + moisture barrier) is a huge advantage for installations on concrete in basements or slab-on-grade homes common in Canada.

Key Features and Benefits: WB MONO MS Performance Plus comes with a host of benefits that make it stand out as a premium wood floor glue:

- High-Performance Bond: This adhesive provides a strong, high-performance bond suitable for all kinds of wooden floors, including solid hardwood and multi-layer engineered boards. It complies with ISO 17178 standards as an elastic adhesive, meaning it remains flexible after curing. That elasticity allows the wood planks to expand and contract with humidity changes (important in Edmonton’s dry winters and humid summers) without stressing the bond. It also helps reduce footstep noise, contributing to a quieter floor.

- One-Component, Easy Application: WB MONO MS is a ready-to-use mono-component adhesive – no mixing of parts or catalyst needed. You simply open the pail and start troweling, which makes it convenient for both professionals and DIY enthusiasts. The adhesive’s consistency offers excellent “ridge” formation, meaning the trowel lines hold their shape for good flooring contact. It’s noted to be easy to clean as well; any adhesive that gets on the surface of prefinished flooring can be wiped off without damaging the finish (ideally while still wet).

- Environmentally Friendly: This product is formulated with no solvents, water, isocyanates or amines. That means very low odor and low hazardous chemicals. It has a very low VOC emission rating (EMICODE EC1 PLUS certified), making it safe for indoor air quality. Installers won’t be breathing strong fumes, and homeowners don’t have to worry about lingering chemical smells. This is a big improvement over older urethane adhesives that contained solvents or isocyanates – WB MONO MS Performance Plus is a modern eco-friendly flooring glue option.

- Versatile Use Cases: Because of its strong bond and flexibility, WB MONO MS is suitable for installing hardwood on various subfloors. Whether you’re gluing down on a concrete foundation, a wooden subfloor, or even gluing wood over an existing tiled floor during a renovation, this adhesive can handle it. It’s also approved for use with in-floor heating systems (radiant heat), maintaining its bond despite temperature changes. The adhesive’s moisture-barrier capability (when applied as a full spread) is useful for projects where you have slight residual moisture in a concrete slab – up to about 4% moisture content (≈85% relative humidity) in the concrete can be managed by this adhesive’s membrane effect if spread uniformly. This gives extra peace of mind when installing wood floors below grade or on slabs in our Alberta climate.

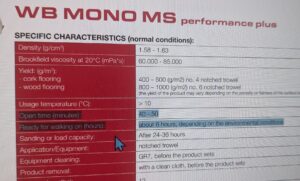

Application Method and Trowel Requirements for WB MONO MS

Applying WB MONO MS Performance Plus is straightforward, but using the right trowel and technique is important to get the best results (and to meet the product’s specifications). Trowel type: The manufacturer recommends using a Notch No. 6 trowel (5/16″ x 3/16″ x 1/2″) for most wood flooring installations. Some engineered hardwood manufactures recommend 3/16-in x 1/4-in x 5/16-in V-Notch Flooring Trowel. These notched trowel size will spread the adhesive at the correct thickness to ensure a good bond and adequate coverage. Using the correct notch is key – too little adhesive can cause bond failures, and too much can cause excess squeeze-out or longer curing times. Always check with the specific brand requirements for installation guidelines.

Spread rate (Coverage): With the No.6 trowel, a standard pail of WB MONO MS covers roughly 162 square feet per pail. (The pail size is typically 15–16 kg of adhesive). In metric terms, the spread rate is about 800–1100 grams per m² of subfloor. The exact coverage will vary based on the flatness of the subfloor and the type of wood floor (smoother, flatter substrates and smaller wood pieces use less adhesive; uneven surfaces or wide planks use more). It’s always wise not to “stretch” the glue too far – full coverage ensures a long-lasting floor bond. If using the adhesive for cork flooring or thinner materials, a smaller notch (e.g., No.4) could be used, yielding about 400–500 g/m² coverage (but for standard hardwood, stick to the recommended trowel).

Working time: WB MONO MS Performance Plus offers a decent open time of around 50–60 minutes. This means after you spread the adhesive on the floor, you have up to about an hour to lay your wood flooring pieces into it before it starts to skin over. This relatively long open time is helpful for positioning boards, especially for less experienced installers working at a slower pace. (Keep in mind that higher humidity can shorten open time, while cooler conditions might extend it slightly – always monitor the adhesive and don’t spread more than you can cover within about 30-40 minutes to be safe).

After the wood is laid into the adhesive, initial curing happens within hours. WB MONO MS is typically “ready for walking on” after about 12–18 hours of curing time. Practically, this means you should allow the glued floor to set overnight before subjecting it to light foot traffic. Avoid moving furniture or heavy objects onto the floor until the adhesive has had more time (at least 24 hours, preferably 48 hours, to cure). The final cure (full setting) is reached in about 48–72 hours, after which the bond reaches maximum strength. It’s best to wait this period before doing any sanding (if it’s an unfinished floor) or before expecting the adhesive to resist full stress and loads.

Advantages and Ideal Use Cases of WB MONO MS Performance Plus

WB MONO MS Performance Plus is often praised as a “problem solver” adhesive thanks to its versatility and strong performance. Some advantages and use cases include:

- Moisture-Prone Subfloors: If you’re installing wood flooring on a concrete slab and are concerned about moisture, WB MONO MS used with a full-spread application can serve dual-purpose as a moisture barrier. This is ideal for basements or ground-level slabs in Edmonton homes, where moisture vapor transmission can be an issue. Rather than needing a separate membrane or epoxy primer, the adhesive itself (applied evenly) will protect the wood from moderate moisture coming through the concrete. This simplifies the installation and saves time. (Note: always test your concrete moisture levels; extremely high moisture might require additional sealing – adhesives have their limits as noted by the manufacturer.)

- Wide Range of Wood Floors: This adhesive is suitable for all types of wood flooring, which means you can use it for solid hardwood planks, engineered hardwood, bamboo, cork tiles, parquet mosaics, etc.. For instance, solid oak, maple, or hickory floors can be glued down with WB MONO MS without worry – the adhesive’s elastic property accommodates the seasonal movement of solid wood. It’s also great for engineered wood (which is dimensionally more stable), providing a strong yet slightly flexible hold. Even cork flooring can be installed with it, as the adhesive can double as a sound-dampening layer under the cork.

- Renovation Over Existing Surfaces: If you have an existing tile or stone floor that you’d like to cover with wood instead of tearing it out, WB MONO MS is a good choice. It can bond wood flooring to non-absorbent surfaces like ceramic tile, marble, or terrazzo – surfaces where many standard glues might not stick well. Just ensure the existing floor is well-bonded (no loose tiles), cleaned, and scuffed or primed if required for better grip. This capability can save a lot of demolition work in renovations.

- Health and Indoor Air Quality: For projects where occupants are sensitive to smells or chemicals – for example, installing flooring in an occupied home, or in schools, medical facilities, etc. – WB MONO MS is advantageous because it’s low VOC and solvent-free. There’s minimal odor and no harmful off-gassing during curing, so the space remains livable. It’s certified as EC1 PLUS (very low emissions), indicating it meets strict European standards for indoor air quality. Homeowners who prioritize green building materials or who have allergies/respiratory concerns will appreciate this aspect.

- Ease of Cleanup: Anyone who has worked with wood flooring glue knows that cleanup can be a challenge. This adhesive is formulated to be easy to clean off the floor’s surface. If you accidentally get some on the top of a prefinished plank, it won’t etch the finish or leave oily stains as some older adhesives did. You should wipe it up while it’s still wet (using a cloth, possibly with a little mineral spirits if needed) for best results – and WB MONO MS won’t stain your hands heavily either during handling. This forgiving nature means a cleaner installation and less time spent scrubbing off glue smears.

WB MONO MS Performance Plus is readily available in Edmonton and stocked at Quality Red Tag Floors. It’s offered in both 16 kg pails and convenient sausage tubes. The sausage format is especially useful for glue-assist installations where a full adhesive spread is not required.

Glue Assist Explained:

Glue assist is a hybrid installation method that enhances the performance of mechanically fastened hardwood floors—especially wide plank or solid wood. A bead of adhesive is applied to the back of each plank (typically in an “S” pattern or straight line) before nailing or stapling it into place. This approach improves bond strength, minimizes movement, reduces squeaks, and helps prevent seasonal gaps. It’s ideal in dry climates like Edmonton where wood expansion and contraction can be more pronounced. Adhesives like WB MONO MS Performance Plus, when used in sausage tubes, make glue assist quick and efficient without the mess of a full trowel spread.

Bona R851 Wood Floor Adhesive Overview

Bona R851 (also marketed as Bona Quantum R851) is a one-component, silane-based hardwood flooring adhesive made by Bona – a renowned brand in the wood flooring industry. Bona R851 is a moisture-curing adhesive that contains no water or solvent; it relies on a reactive silane-modified polymer that cures by reacting with moisture in the air and subfloor. Like the WB MONO MS, Bona R851 is an elastic adhesive that remains slightly flexible once cured, allowing the wood floor to move naturally with seasonal humidity changes. This adhesive has become very popular among flooring professionals in North America for its strong performance and user-friendly properties.

Key Features and Benefits: Bona R851 is often described as a “next-generation” wood flooring glue with features that cater to both installer needs and floor performance:

- Exceptional Green Grab: One of Bona R851’s standout features is its excellent initial “green grab” or tack. This means when you press a hardwood plank into the adhesive, it tends to stay put and resist sliding or lifting. The flooring “grabs” quickly. For installers, this is helpful because boards won’t shift out of place even before the adhesive fully cures. It’s especially useful when installing larger planks or when working on a vertical surface (like stair treads or perhaps up a wall) – the strong tack holds pieces firmly. High green grab can make the installation faster and ensure tighter joints.

- No “Memory” Effect: Bona R851 is formulated such that once the wood is in place, it prevents floor seams from creeping or opening up (“no memory”). Some adhesives might allow a board to slightly move back (due to the wood’s internal stresses trying to straighten out). R851 keeps the boards exactly where you set them, so your floor won’t develop gaps after installation. This contributes to a stable, gap-free floor over time.

- Fast Strength Development: Within a day of installation, R851 develops high bond strength. It has a rapid shear strength development, allowing the floor to be ready for furniture and foot traffic in one day. In practice, light foot traffic is often possible in 8–10 hours after install, and by the next day (12–24 hours) you can move furniture back or install baseboards and heavy fixtures. This quick curing is a plus for projects on a tight timeline – for example, if you’re renovating a room and want to minimize downtime. (It’s always wise to test before heavy moving, but many pros indeed walk on the floor the next morning without issues.)

- Easy to Apply and Clean: Bona formulated R851 with the installer’s comfort in mind. It spreads smoothly and is designed to cause no excessive arm fatigue during troweling. This is a notable claim because some wood adhesives are very thick or sticky, making them hard to trowel over large areas. R851’s consistency strikes a balance – thick enough to hold trowel ridges, but not so stiff that you’re sore after spreading a bucket of it. Additionally, it’s easy to clean off prefinished wood surfaces – it will not damage or etch the factory finish of hardwood planks if you wipe it off. Any smears on the floor or tools can be cleaned up (best while still fresh) and it even claims to not stain hands significantly, which installers appreciate when they don’t end the day with hands covered in black tar-like goo (a common complaint with older urethane glues).

- Unsurpassed Ridge Stability: When troweled, Bona R851 holds distinctive ridges that do not collapse – this is referred to as ridge stability. The benefit here is that those adhesive ridges ensure maximum adhesive transfer to the backside of the wood flooring. In other words, the glue stays combed up tall enough so that when you press the wood down, the ridges spread and coat nearly 100% of the plank underside. Good transfer means no hollow spots under your floor and a solid bond across the whole board. Even for wide planks, Bona R851’s ridge stability helps achieve full coverage bonding.

- Environmental Safety: Bona R851 is very environmentally friendly. It is a Zero VOC product (contains no volatile organic compounds), meeting strict indoor air quality standards (LEED and GREENGUARD certifications). It’s also water and solvent free, and isocyanate-free, so it shares the same “safe for your lungs and nose” profile as the WB MONO MS. This adhesive won’t introduce harmful odors – an important consideration for residential projects where people may be present during or right after installation. Bona R851 is compliant with health safety regulations like California’s Proposition 65 and is even rated to contribute to LEED credits for low-emitting materials. For the installer, this means no special respirators needed beyond normal ventilation, and for the homeowner, it means a healthier home.

- Moisture Protection: Similar to its competitor, Bona R851 can also function as a moisture control adhesive when used properly. Standard application of R851 provides moisture vapor protection up to about 15 lbs ASTM (or ~85% RH) of concrete moisture*. With an enhanced trowel technique (Bona’s Moisture Barrier (MBP) trowel attachment), it can handle up to 18 lbs or 95% RH – essentially acting as an all-in-one adhesive and moisture barrier. This is particularly beneficial for certain areas of Canada where concrete subfloors might retain higher moisture. Rather than applying a separate epoxy sealer, installers can just use R851 with the special notched trowel that applies more adhesive per square foot (achieving a thicker membrane). It’s worth noting that while it offers this protection, it will not protect against standing water or water intrusion from above – it only handles vapor from below. So still fix any sources of water leaks. But for gluing wood floors on concrete in basements or condos, Bona R851 provides an extra layer of security against moisture issues.

- Suitable for Many Subfloors: Bona R851 is approved for use on a wide array of subfloor materials. It works on concrete (on, above, or below grade), plywood and OSB subfloors, cork underlayments, and even directly over well-bonded stone or ceramic tiles and terrazzo. (Like any adhesive, the surface must be clean, dry, and properly prepared – e.g., scuff-sanded and free of contaminants like paint or old adhesive residue.) The only cautions are it should not be used over sheet vinyl, VCT, or old cutback adhesive residue, and not over concrete with curing compounds or on very wet slabs. But in general, if you have a flat, sound subfloor, Bona R851 will likely adhere to it and keep your wood floor in place for the long haul. It’s also approved for radiant heated floors (common in some modern homes) without issues.

Bona R851 is widely available in Canada through wood floor adhesive suppliers and distributors – often sold in 3-gallon (11.34 L) pails which weigh about 17–18 kg. Many wood floor adhesive suppliers in Edmonton and other Canadian cities carry Bona products, as Bona has an established distribution network. If you’re searching for Bona R851 wood floor adhesive suppliers in Edmonton, you’ll find it at professional flooring supply stores or through flooring contractors who can source it. Pricing for a 3-gallon pail is roughly in the $200–$250 CAD range (pricing may vary), reflecting its professional-grade quality. Next, we’ll directly compare WB MONO MS and Bona R851 across key factors to help you decide which might be the better fit for your project.

Side-by-Side Comparison: WB MONO MS Performance Plus vs. Bona R851

Both WB MONO MS Performance Plus and Bona R851 are high-quality, MS polymer (“silane”) wood flooring adhesives with many similarities. Each will serve for most hardwood glue-down applications in Alberta. However, there are subtle differences that might sway your choice depending on your priorities. Below, we compare them on ease of use, performance, curing time, environmental factors, and suitability:

Ease of Use (Application and Handling)

Troweling and Spread: Both adhesives are one-component products that come ready to use – just stir (if instructed) and start troweling. Neither requires any mixing of parts, which is a big plus for ease of use. Bona R851 has been specifically noted as easy to apply with no arm fatigue during spreading. Installers often find that it spreads a bit “creamier” or smoother, maintaining good ridge lines without requiring excessive force. WB MONO MS is also installer-friendly, but it is a very high-viscosity adhesive (to achieve its high bond strength and moisture barrier capability). It holds trowel ridges nicely and is 100% solids (no shrinkage), but some users might find it slightly thicker to push around compared to Bona. In practice, both adhesives spread well with the recommended trowels – a 5/16″ V-notch for larger plank floors in both cases – so neither will run or puddle on you.

Initial Tack: Bona R851 likely has the edge in initial tack (“green grab”). It is marketed for its exceptional green grab strength that keeps flooring strips in place immediately. This means once you lay a board, it’s less prone to sliding if bumped. WB MONO MS also has good tack (as most MS polymers do), but Bona’s formula gets frequent praise for how well it holds instantly. If you’re working alone, Bona’s grab might make the job easier since boards won’t drift as you move on to the next row. On the other hand, a very high tack means you need to position boards carefully on first contact; WB MONO MS’s slightly longer open time and perhaps a tad less instant stick might allow a bit more adjustment before the board grabs firmly.

Open Time and Workability: WB MONO MS offers about 50–60 minutes of open time on the floor, whereas Bona R851’s open time is around 30–40 minutes. In cooler, less humid conditions you might get a bit more working time, but generally WB MONO MS gives you a longer window to work with the adhesive spread out. This can benefit DIYers or meticulous installers who want extra time to position each piece perfectly. Bona’s slightly shorter open time means you should plan to spread smaller sections (or be efficient in laying wood) to avoid the adhesive skinning over. Both products’ open times are ample for professional installers; just be mindful not to trowel the whole room at once. Also, humidity affects curing – Edmonton’s climate can be dry, especially in winter, which might extend open times a little for both adhesives (but don’t rely on that; always observe the adhesive and only spread what you can cover in under half an hour).

Cleanup: Both adhesives boast easy cleanup. Bona R851 will not harm prefinished floor surfaces and can be cleaned off even after it cures without leaving oily stains – it tends to roll up or peel off the finish rather than bond to urethane floor finishes. WB MONO MS is also formulated to be easy to clean and remove before it sets. The general advice is the same: wipe off any excess or smudges while the adhesive is still wet using a cloth (and manufacturer-recommended cleaner, e.g., mineral spirits for Bona or Adesiv’s cleaner for WB). Once cured, these adhesives will require a bit of elbow grease to remove from surfaces, but they won’t have chemically etched the finish like old solvent glues did. Always have some rags handy during installation to keep things tidy.

Verdict on Ease of Use: It’s close. Bona R851 might be slightly easier on the installer due to its smooth spreading and super grab (less tape or bracing needed), whereas WB MONO MS gives a bit more working time which can reduce stress for careful work. Both save time by not needing mixing and by being easy to clean. For a first-time DIY user, either is manageable, but be aware that both are thick products – have a proper notched trowel and perhaps a rubber mallet to tap boards into place. Also, note that both adhesives should be applied at the correct temperature (generally the room and adhesive should be above ~10°C). Store the pails at room temp before use – a cold adhesive is harder to spread.

Performance and Bond Strength

Both adhesives provide excellent long-term performance in holding wood floors securely:

- Bond Strength: Bona R851 advertises unsurpassed final shear strength among its class. Its rated shear strength is around 335 psi after full cure, which is very high – more than enough to keep planks firmly adhered during normal use. WB MONO MS doesn’t publish a specific psi, but as an MS polymer adhesive meeting ISO standards, its strength is also very high (likely in a similar range). In real-world terms, once fully cured, both adhesives will resist the stresses of wood shrinkage, expansion, and foot traffic without letting go. Your wood will break before these bonds do, in most cases. Both also maintain a bond in temperature fluctuations (the Adesiv product is rated stable from -40°C to +80°C once cured, per some data sheets, and Bona works in heated floors).

- Flexibility: A crucial aspect for wood glue is the elasticity to allow slight movement. Both are classified as elastic, elastomeric adhesives. This means instead of becoming rock-hard, they remain a bit rubbery – enough that when wood planks expand, the adhesive can stretch, and when wood contracts, it can compress or “rebound,” keeping the floor attached to the subfloor. This prevents the wood from pulling itself apart or from shear-stresses that could cause delamination. WB MONO MS Performance Plus and Bona R851 are nearly on par here; Bona quotes an elongation of ~250%, and Adesiv’s product also passes the highest elastic standards. In practical use, both work well for wide planks and solid hardwood because of this flexibility. Additionally, this elasticity helps with sound damping – both adhesives contribute to a quieter floor by absorbing sound (WB MONO MS has an IIC 69 rating in tests, Bona R851 was listed with IIC 71 in one test on concrete – the slight difference likely due to test setups; both reduce impact sound compared to a nail-down floor).

- Durability: These adhesives are engineered to last the lifetime of the floor. They are not water-soluble (once cured, water has no effect on them) and are resistant to aging. Both are resilient against temperature changes and won’t become brittle in cold weather or overly soft in heat. Bona R851 has a slight edge in brand reputation simply because it’s been widely used in North America for years with great results, whereas WB MONO MS is a bit newer to the Canadian market (though it has a strong track record in Europe). That said, Adesiv’s adhesive is thoroughly tested and designed for high performance – many installers report it performs on par with, or even better than, some established brands in terms of bond strength and ease of use. So you can expect both to securely hold even challenging installations (like herringbone patterns or warped planks, given proper clamping during install).

- Special Properties: Both adhesives are compatible with underfloor heating and won’t be negatively affected by the cycling of heat. Neither adhesive contains protein or organic fillers that might attract mold – they are purely synthetic polymers, which is good for durability. Also, because they are moisture-cure, they actually cure harder in slightly humid conditions – the ambient moisture in Edmonton (which can be low in winter, so one tip is to slightly humidify the environment to around 40-50% RH during cure if possible). In summer, natural humidity is usually enough. Both adhesives can handle heavy furniture and loads once cured – pianos, refrigerators, etc., are fine on floors glued with these products (just wait the recommended time before moving heavy objects on them).

Verdict on Performance: It’s essentially a tie. Both Bona R851 and WB MONO MS provide robust, long-lasting bonds with the flexibility needed for wood flooring. Bona’s marketing emphasizes shear strength and green grab, while Adesiv emphasizes universal use and moisture barrier performance. But at the end of the day, you can trust either adhesive to keep your hardwood floor flat and bonded for many years, provided installation guidelines are followed.

Curing Time and Drying Schedule

Time-to-cure can affect how quickly you can use the new floor or move on to the next construction steps:

- Walk-On Time: Bona R851 has a slight advantage in that it sets up enough for light foot traffic in about 8–10 hours (often by the next morning if installed in the afternoon). WB MONO MS generally needs a bit longer, around 12 hours (up to 18 hours) before it’s safe to walk on. In practical terms, both are usually ready by the next day. If you finish installing late in the evening, by the next morning Bona’s floor might be ready for careful walking, whereas WB’s might need until later that day. If timing is critical (say, a commercial space that must open the following day), Bona’s faster initial cure is a plus. For residential jobs where you can wait overnight, the difference is minor.

- Furniture and Heavy Traffic: Bona R851 reaches a stage where it can support furniture and heavier loads at around 12–24 hours after installation. By the next day evening, you could typically start moving furniture back carefully. WB MONO MS would be safer to give a full 24 hours or slightly more for heavy items. It might still be green at 12 hours, so while you could carefully walk, you wouldn’t want to drag a heavy couch across it too soon. When in doubt, waiting 24 hours for either adhesive before moving heavy furniture or allowing pets, etc., is a good practice. Both adhesives fully cure in about 2–3 days (48–72 hours) under normal conditions, but Bona indicates you can even sand an unfinished floor after 24 hours, showing how quickly it gains strength.

- Finish and Sanding: If you are installing unfinished hardwood that needs to be sanded and finished in place, Bona R851 will allow sanding after 24 hours. WB MONO MS would likely advise waiting possibly 36–48 hours to be safe (the tech sheet says final setting 48-72h, but “ready for walking” at 12-18h suggests by 24h it’s largely set). If you attempt to sand too early, the boards could shift or adhesive might not have the strength to resist the vibration – so adhere to manufacturer guidance. For prefinished floors, this isn’t a concern.

- Moisture Barrier Cure: One thing to note – if you are using these adhesives as a full-spread moisture barrier (applying extra thick with no gaps), the cure might be a bit slower because there’s more material to cure and less exposure to air. For example, Bona’s MBP trowel application might take a bit longer to firm up (hence their spec of 18lbs/95% at 30-35 sq ft/gal coverage likely assumes a longer cure). Similarly, a fully continuous layer of WB MONO MS will cure from the edges inward. In these cases, err on the side of caution and allow an extra day if possible before heavy traffic.

Verdict on Curing Time: Bona R851 wins by a small margin for speed. It’s formulated for rapid strength gain, which can shave a few hours off the wait to use the floor. WB MONO MS is not far behind – most installations with either adhesive will be essentially cured to a usable state within 24 hours. If your project demands the absolute fastest turnaround, Bona might be preferable. Otherwise, both will require an overnight wait, which is standard for glue-down floors (and definitely much faster than old-fashioned adhesives that sometimes needed 2–3 days before you dared walk on them).

Environmental and Health Considerations

For the health-conscious consumer or contractor, both adhesives are excellent choices compared to older alternatives:

- VOC Content: WB MONO MS Performance Plus is classified as very low VOC (EC1 PLUS) and practically has negligible solvent content. Bona R851 is listed as ZERO VOC. In essence, neither will contribute meaningful VOCs to your indoor environment. This is in stark contrast to some older flooring glues in Canada that were solvent-based and would produce strong odors (and even violate today’s VOC regulations). With these modern MS adhesives, you can install flooring in an occupied home without evacuating the residents due to smell.

- Hazardous Chemicals: Neither product contains isocyanates or halogenated solvents. WB MONO MS is explicitly “free from isocyanate and amines”, and Bona R851 is isocyanate-free and solvent-free as well. Isocyanates (found in some polyurethane adhesives) can cause allergic reactions and require more protective measures. The absence of these means safer handling – though you should still wear gloves and ensure ventilation, as with any chemical product.

- Certifications: Bona R851 carries UL GREENGUARD Gold certification for indoor air quality and meets strict environmental building standards (LEED EQ credit requirements). WB MONO MS’s EC1 Plus rating is an internationally recognized symbol of a low-emission product. Both adhesives align with the trend toward eco-friendly building materials. If you’re a flooring supplier or contractor catering to clients who ask for “green” products, you can confidently point to these adhesives as part of a low-emission installation system.

- Cleanup and Disposal: Because they have no hazardous solvents, disposal of small amounts of cured adhesive in normal construction waste is typically permissible (check local regulations). Any tools can be cleaned with relatively mild solvents (mineral spirits or manufacturer’s cleaner) which are also low in smell compared to xylene or other aggressive cleaners that were once needed.

- Allergy Concerns: Some individuals have chemical sensitivities; using a zero-VOC adhesive can be a selling point. Furthermore, since these products don’t contain water, they won’t introduce moisture that could lead to mold under the floor. Also, their elasticity can reduce squeaks (by keeping boards bonded) which indirectly means less maintenance and no need to use additional products down the line.

Verdict on Environmental Factors: Both adhesives are top-tier in this category – it’s essentially a draw. They are among the best choices for flooring glue in Canada where low VOC, safe formulations are now expected. Whether you choose Bona R851 or WB MONO MS, you’re ensuring an installation that is friendly for indoor air quality and for the installer’s health.

Suitability for Different Wood Types and Subfloors

When it comes to what floors you can install and where, these adhesives are extremely versatile:

- Wood Floor Types: Solid Hardwood: Both are suitable for 3/4″ solid hardwood of various widths (from narrow strip to wide planks). Bona even specifies usage up to 5″ wide with one trowel and up to 9″ wide planks with a larger notch – indicating it’s formulated for big planks. WB MONO MS similarly can handle wide boards (it mentions up to 18 cm wide solid T&G, which is ~7 inches, or 20 cm for engineered, and presumably more with proper application). For very wide boards (like 10″+ modern planks), either adhesive will work, but you must use the proper trowel for full coverage (and possibly glue-assist with nails or clamps until set, just as an added measure). Engineered Wood: Both adhesives excel with engineered hardwood, which is typically dimensionally stable and thinner. They will easily bond the plywood or HDF backer of engineered planks to the subfloor. In fact, these adhesives are often overkill in strength for engineered wood – which is a good thing as you’ll never have a plank come loose. Parquet / Herringbone / Chevron: These patterns require a strong initial grab to keep pieces from sliding out of alignment. Bona R851’s tack is very useful here. WB MONO MS’s slightly slower grab might mean you use some painter’s tape to hold patterns until initial set, but it will certainly keep them bonded long-term. Both can be used for wood mosaics, fingerblock parquet etc., as they fill gaps and keep pieces well adhered (just use the appropriate smaller-notch trowel for thinner pieces to avoid excessive squeeze-out). Bamboo and Exotic Woods: These adhesives work on bamboo and dense exotics (rosewood, ipe, etc.) too – since they have high shear strength and stick to even oily woods (due to being chemically reactive rather than purely evaporation-cure). Always ensure the wood manufacturer approves glue-down for that species; if yes, these glues will do the job.

- Subfloors: Concrete Slabs: Both are made to glue wood directly to concrete. They also each provide moisture vapor protection (up to moderate levels) as discussed. If you have a newly built home in Edmonton with a concrete main floor or basement, these adhesives allow you to install a beautiful hardwood floor directly on the slab (after proper prep like leveling and cleaning) without needing plywood underlayment. Plywood or OSB Subfloor: In a typical wood-frame house (above a basement or crawlspace), you might have a plywood subfloor. These adhesives can glue hardwood directly to that as well, though often in such cases people opt to nail/staple solids. However, for sound isolation (e.g., second floor condos, or if you want to reduce noise in a main-floor over basement), glue-down on wood subfloor is an option. Both adhesives will bond well to plywood or OSB (make sure it’s dry and within moisture spec). Tile/Stone: As mentioned, WB MONO MS specifically lists marble, tiles, and terrazzo as acceptable surfaces, and Bona lists stone, ceramic, terrazzo – so both will stick to those slick surfaces when they are properly prepared (cleaned of any wax or grease, and scuff-sanded to provide a tooth). This is fantastic for renovation scenarios; for example, a homeowner can have their contractor glue hardwood over an old tile floor in the kitchen rather than jackhammering it out, saving time and mess. Cork Underlayment: If you’re using a cork or rubber sound underlayment, you can use these adhesives either to glue the cork down and then wood on top (some installers do a double glue), or in Bona’s case, they even show it can be used to adhere wood over cork in one step. Always follow each underlayment’s instructions, but it’s good to know these adhesives are compatible with such materials. Metal Surfaces: Interestingly, Adesiv notes WB MONO MS can even bond wood to metal (after appropriate degreasing). That’s a rare case (perhaps relevant for steel staircases or transitions), but it speaks to the adhesive’s strong bonding capability on non-porous substrates. Bona doesn’t explicitly mention metal, but as a silane polymer, it likely also can grip metal if it’s clean; however, that’s a non-standard application.

- Edmonton Climate Considerations: Edmonton’s dry winter air can cause wood floors to shrink – having an elastic adhesive like these means the floor is less likely to split or squeak compared to rigid attachments. Both adhesives are good choices for solid hardwood in our climate for that reason. Additionally, if installing on concrete in an unheated space (like during construction in winter), note both adhesives require temperature control during installation and curing (ideally the subfloor should be at least 15°C or so). They can cure in lower temps but slowly. So ensure the site is warmed and at normal living conditions for 48 hours prior and after installation for best results.

Verdict on Suitability: Both adhesives are extremely versatile, handling virtually any wood flooring type and common subfloor in Edmonton homes or businesses. There’s no clear winner as each can tackle solids, engineered, etc., on concrete or wood subfloors. If you have a unique case like bonding to metal or an old stone floor, WB MONO MS explicitly supports it and might be a go-to. If you’re doing a pattern install where initial grab is vital, Bona R851’s quick tack might make life easier. But in general, choose either based on availability or minor preferences – neither will limit your project scope.

Availability and Support in Canada

Lastly, a quick note on getting these products: Both WB MONO MS Performance Plus and Bona R851 are available in Canada, and specifically you can find them through flooring glue suppliers in Edmonton and across the country. Bona is a well-known brand with distribution through many flooring retailers and wholesale suppliers – you can likely walk into a flooring supply shop in Edmonton (or even large tool stores or online flooring retailers) and find Bona R851 in stock. WB MONO MS, being an Italian product, is distributed in Canada through select specialty flooring distributors (such as Magna Hardwood or other importers). It may not be on the shelf of every big-box store, but most specialized hardwood flooring suppliers either carry it or can order it. Both adhesives come with technical data sheets and support. Bona, for instance, has technical support lines and a lot of online documentation (and even a “Where to buy Bona” tool on their website). Adesiv’s product is newer here but the local distributors can provide guidance, and the product documentation is comprehensive.

From a supplier’s perspective, stocking these adhesives is smart because they cater to the high end of the market – professionals who want quality and homeowners who are educated about “doing it right.” If you are a contractor, using these premium adhesives can be a selling point to clients (“We use low-VOC, high-performance European adhesives for your floor”). If you’re a DIYer, you might spend a bit more on these glues than a bargain option, but you’re investing in the longevity of your floor and avoiding potential failures (and considering the cost of hardwood flooring itself, the adhesive is not the place to skimp).

Tips for Applying WB MONO MS Performance Plus and Bona R851

No matter which of the two adhesives you choose, proper application technique is vital for a successful installation. Below are practical tips and guidelines to ensure your glue-down wood flooring goes smoothly:

- Surface Preparation: Make sure your subfloor is clean, dry, and level before spreading any adhesive. Remove any old adhesive, paint, dust, or debris – a clean surface ensures maximum bonding. For concrete, fill any cracks or depressions with a leveling compound and let it dry (subfloor should be flat within 3/16″ over 10 feet). Check moisture levels: concrete should be within the adhesive’s limits (use a moisture meter or calcium chloride test – e.g., Bona R851 without moisture barrier is okay up to 12 lbs MVER, and with full spread up to 18 lbs; WB MONO MS wants concrete <4% moisture unless used fully spread as barrier). Wood subfloors should be checked for moisture balance as well (usually <12% MC). In Edmonton’s climate, ensure the building is acclimatized – heating or AC should be on so that conditions are normal during installation.

It might sound surprising, but cold adhesive is much harder to spread. For optimal workability, store glue buckets at room temperature (around 20°C) for at least 24 hours before use. In winter, if the adhesive has been sitting in a cold van or garage, bring it indoors to warm up before application. This helps maintain a smooth consistency and makes troweling significantly easier.

Distributors of both WB MONO MS and Bona R851 adhesives take care to store their products in climate-controlled warehouses year-round. In fact, the Canadian distributor for WB MONO MS goes a step further—they avoid ordering new stock during the winter months to limit cold exposure during transit. Instead, they purchase and receive their full winter supply during the warmer seasons, ensuring it is properly acclimatized before being stocked. With a typical shelf life of 18 months, this approach guarantees consistent product quality and performance throughout the year.

- Tools and Trowel Selection: Use the manufacturer’s recommended notched trowel for the flooring you’re installing. Trowel notch geometry is calibrated to deliver the right amount of adhesive. For example, for standard 3/4″ hardwood planks, use a 1/4″ x 1/4″ V-notch (such as Bona’s 1250G trowel) which yields ~60 sq ft per gallon coverage. For wider planks up to ~8–9″, go up to a 5/16″ x 5/16″ V-notch. For smaller parquet or engineered planks, a smaller notch (3/16″ or 5/32″) may suffice. WB MONO MS specifically notes a No.6 (5/16″) trowel for general wood floors. The goal is to achieve near 100% coverage on the back of the wood. Keep spare trowel blades handy – if the notches wear down, you won’t spread enough glue. (Pro tip: The cost of a trowel is minor compared to the floor; replace the trowel for each new pail or when worn to ensure proper spread rate.)

- Spreading the Adhesive: Work in small sections that you can cover with flooring within the open time. A good approach is to trowel adhesive for maybe 2-3 rows of flooring at a time (roughly a 2–3 foot wide strip of adhesive across the room). Hold the trowel at a 45–90° angle to the floor and spread with a smooth, semicircular or zigzag motion, creating even ridges. Make sure you don’t leave any puddles or clumps; the ridges should be uniform in height. Do not spread more adhesive than you can lay wood onto within about 20-30 minutes – even though the advertised open time might be longer, it’s best to play it safe to avoid the glue starting to skin. In practice, by the time you use up one spread area with boards, the next spread will be just right to continue. If an area of adhesive skins over (you touch it and it doesn’t stick to your finger), scrape it off and apply fresh adhesive – never lay wood into skinned adhesive, as it won’t bond properly.

- Laying the Flooring: Set each plank into the wet adhesive and push it firmly down. You should see the adhesive transfer to the back of the plank; occasionally lift a board you just put down to check that you’re getting full coverage. If not, you might need a bigger trowel or back-buttering. Slide or press the planks into their final position – the adhesive’s grab will start to hold them. Use spacers at walls for expansion gaps as usual. For tongue-and-groove hardwood, make sure joints are tight. You can use a rubber mallet and a tapping block to snug pieces together (just be careful not to cause adhesive to splatter when you hit boards). For prefinished wood, wipe any adhesive off the surface immediately – both Bona R851 and WB MONO MS won’t damage the finish if cleaned promptly. Keep a towel or wipes at hand. Work your way out of the area; plan an exit strategy so you’re not glued into a corner! If doing a large area, consider dividing the room and leaving a “clean” path you can walk on, then backtrack and glue that last area.

- Maintain Expansion Gaps: Even with elastic adhesive, you must leave the recommended expansion gap (typically 1/2″ around the room perimeter or as specified by the flooring manufacturer). The adhesive will hold the floor in place, but the wood still needs room to expand overall. The elastic glue isn’t a substitute for expansion space – it just helps each board move slightly without stressing the bond.

- After Laying Each Section: It can be helpful to roll the floor with a 75-100 lb roller (or simply walk carefully across each board, or use a floor roller tool) to ensure good contact. Some installers also strap or weight the floor if needed (for instance, if a board is bowed and wants to lift, weight it down until the adhesive sets). Both adhesives have good grab, so widespread weighting is usually not needed, but always address any areas not fully flat.

- Cleanup During Installation: As mentioned, clean any glue off the wood surface right away. For Bona R851, a damp cloth or mineral spirits on a cloth can remove residue. Do not use water (water isn’t effective on these adhesives). For WB MONO MS, Adesiv makes a cleaner (GR7) for uncured adhesive, or use denatured alcohol/mineral spirits carefully. Also keep glue off your hands and tools; a bucket of sand or sawdust can help scrub it off your trowel between spreads, or use disposable trowels.

- Post-Installation Curing: Once a section or the whole floor is laid, prevent any traffic on it for the recommended time. Ideally, block off the area for at least 12–24 hours. In a home, that might mean planning to stay off that floor overnight. In a public or commercial space, use caution tape or signage. Remember that at 8-12 hours, adhesive is only partially cured – avoid any dynamic loads (don’t let pets run on it, don’t slide furniture). If you must move on it, do so gently and avoid stepping on the very edges of boards as those could depress and break the adhesive bond before it’s firm.

- Finishing Up: After 24 hours (with Bona) or around 24–48 hours (WB MONO MS), you can remove any expansion spacers, install baseboards or transitions, and move furniture back. If the floor is unfinished wood, you can proceed to sanding and finishing once the adhesive cure time has passed (again, Bona says after 1 day you can sand; with WB, 2 days cure is conservative). When nailing trim, be careful not to nail through the wood into the subfloor (which could pin a floating section and negate the expansion gap – nail trims to the wall, not the floor).

- Long-Term Maintenance: Floors installed with these modern MS adhesives generally require no special maintenance related to the adhesive. If the home experiences extreme swings in humidity, use humidifiers or dehumidifiers to keep conditions stable – this helps the wood and the adhesive by minimizing stress. In case a board ever needs to be replaced, note that these adhesives do such a good job bonding that removing a glued board will be challenging (usually it means cutting out the board in pieces). The strong bond is a positive for performance, but just know glued planks are not meant to be taken up intact.

By following these application tips, you’ll maximize the performance of either adhesive. Always read the manufacturer’s instructions that come with the product (both Bona and Adesiv provide detailed technical data and installation guidelines). Each product has specific nuances, but the above covers the common best practices.

Conclusion: Choosing the Right Wood Floor Adhesive in Edmonton

When comparing WB MONO MS Performance Plus vs. Bona R851, the good news is you really can’t go wrong – both are premium wood floor adhesives that will meet the demands of glue-down installations in Edmonton, Alberta and beyond. They represent the latest in adhesive technology (silane-modified polymer glues) which offer strong bonding, flexibility, and environmental safety.

To summarize the comparison:

- WB MONO MS Performance Plus shines with its moisture barrier capability and slightly longer open time. It’s an excellent choice if you anticipate higher subfloor moisture or need an adhesive that can bond to tricky surfaces. Its Italian-engineered formula is free of harmful chemicals and has proven performance in tough scenarios. Edmonton contractors might lean on WB MONO MS for projects like basement installs or renovations over existing tile, taking advantage of its versatility. Just ensure you get it from a supplier that stocks Adesiv products (it’s available through Canadian distributors, especially in Western Canada).

- Bona R851 stands out for its ease of use and quick curing. It’s a tried-and-true option for many flooring professionals. If speed and initial grab are priorities – for example, a large area where you want to keep work flowing with minimal bracing – Bona’s adhesive is a winner. It’s widely available (any store catering to hardwood flooring in Edmonton is likely familiar with Bona R851) and comes with the backing of Bona’s reputation in the flooring industry. Additionally, if you or your clients are specifically looking for “Bona R851 wood floor adhesive suppliers”, you’ll find several in the region due to Bona’s strong distribution network.

In terms of cost, both are premium products and are priced accordingly, but the difference between them is usually negligible compared to the overall project cost. It’s worth investing in a top-quality adhesive to avoid failures like loose boards or moisture damage, which can be very costly to fix later.

For homeowners reading this: using either of these adhesives for your wood floor installation in Edmonton means you’re getting a state-of-the-art product that will help your floor last for decades. They accommodate the natural movement of wood through our dry winters and humid summers, and they won’t fill your home with toxic fumes. Make sure your installer is knowledgeable about these glues – or if you’re doing a DIY install, be prepared to follow the guidelines closely. The result will be a beautiful, squeak-free wood floor that’s bonded as securely as if it were part of the subfloor itself.

For contractors and flooring suppliers: offering WB MONO MS Performance Plus and Bona R851 as options to clients gives you a competitive edge. You can address clients’ concerns about moisture (“we can use an adhesive that also acts as a moisture barrier”), indoor air quality (“these adhesives are low-VOC and safe”), and longevity (“these products are high-performance, used by professionals worldwide”). Both products are readily available in Canada, so supply shouldn’t be an issue – you can obtain them via Edmonton-based distributors or direct order. Keep some inventory if you regularly do glue-down jobs, as having it on hand can allow you to respond quickly to project needs.

Final thoughts: The choice between WB MONO MS and Bona R851 may come down to personal preference, specific project requirements, or simply what your trusted supplier has in stock at the moment. Many installers actually report that the two perform very similarly in the field. If possible, you might even consider trying both on different projects to see which you prefer working with. Regardless, using either means you are employing a modern solution for wood floor installation that will contribute to a successful, durable outcome.

Both WB MONO MS Performance Plus and Bona R851 are top-tier wood floor adhesives available in Edmonton and across Canada, backed by solid research and development. By understanding their features and following proper application methods, you’ll ensure your hardwood flooring is glued down for success. Now all that’s left is to get your flooring glue and start that installation – your beautiful new wood floors await, securely bonded for years of enjoyment!

Sources: Relevant product data and guidelines were referenced from Adesiv’s WB MONO MS Performance Plus technical literature, distributor information, and Bona R851 technical data sheets and product brochures, as well as industry installation best practices. Always consult the latest manufacturer documentation for the most accurate information. Enjoy your flooring project, and rest assured that with the right adhesive choice, your wood floors will be stuck with you (in a good way) for the long run!

Recent Comments